Layin' on the Lumber - The CCM Hockey Stick

The first hockey sticks were carved by Mi'kmaq natives of Nova Scotia. They used a wood called hornbeam, also known as ironwood because it is so strong. The best trees for making sticks had roots that grew out in the correct angle for a stick blade. When the hornbeam was used up, the carvers turned to yellow birch, another hard wood. The early sticks looked more like today's field-hockey sticks, with a blade that curved up. They were also shorter and heavier. As hockey grew in popularity, the Native carvers could not make the sticks fast enough for everyone who wanted one. The Starr Manufacturing Company of Dartmouth, Nova Scotia, began making hockey sticks. They called their sticks Mic Mac, after the original makers. These sticks were popular in the 1930s.

The first hockey sticks were carved by Mi'kmaq natives of Nova Scotia. They used a wood called hornbeam, also known as ironwood because it is so strong. The best trees for making sticks had roots that grew out in the correct angle for a stick blade. When the hornbeam was used up, the carvers turned to yellow birch, another hard wood. The early sticks looked more like today's field-hockey sticks, with a blade that curved up. They were also shorter and heavier. As hockey grew in popularity, the Native carvers could not make the sticks fast enough for everyone who wanted one. The Starr Manufacturing Company of Dartmouth, Nova Scotia, began making hockey sticks. They called their sticks Mic Mac, after the original makers. These sticks were popular in the 1930s.

The first recorded production of hockey sticks in Canada was carried out by the Mi'kmaq natives of Nova Scotia, who carved them out of a wood called hornbeam, also known as ironwood because of its strength. When the hornbeam was used up, the carvers turned to yellow birch. The early sticks looked like field-hockey sticks with a blade that curved up. They were shorter and heavier than the sticks that came to be used in later years.

As hockey grew in popularity, the Native carvers couldn't keep up with the demand. As a result, the Starr Manufacturing Company of Dartmouth, Nova Scotia, began manufacturing hockey sticks and calling them Mic Macs in honour of the original makers.

Having distributed sticks and other hockey equipment for various companies over the years, in 1933 Canada Cycle & Motor acquired an interest in the Jos. Choquette Wood Specialties Co. Ltd. of St. Jean, Quebec. The Quebec company had been founded in 1919 by brothers Joe and Ed Choquette, who started out making hockey sticks in the rear of their sporting goods store on City Hall Avenue in Montreal before moving production to the factory in St. Jean.

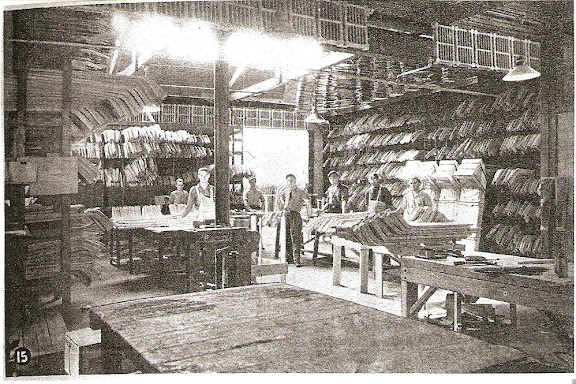

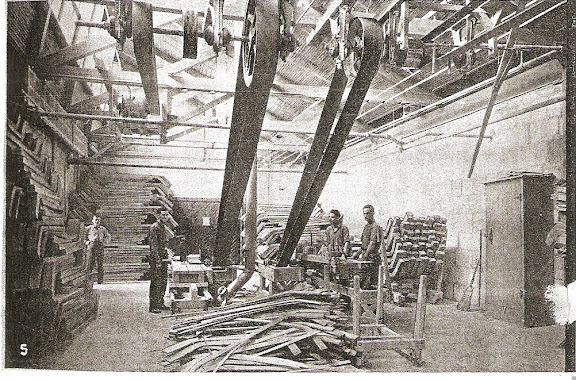

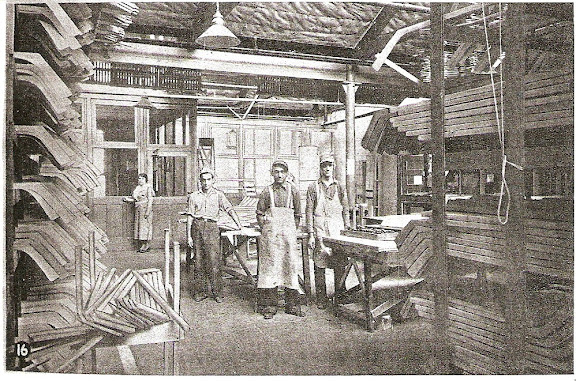

Three different views of the Choquette factory in St. Jean, Quebec

According to the Choquette brothers for a hockey stick (usually elm or ash) to be strong, the wood had to be light, straight and have few marks on it. On one occasion to demonstrate the truth of the claim, Ed Choquette stepped up to the huge rack of sticks in the Choquette store and selected a stick. He then placed one end of the stick on the floor and the other against the rack and jumped on it. While Ed was tossed unceremoniously into the air, the stick stayed in one piece prompting Ed to exclaim: “Now there's a stick you can play hockey with!” (1)

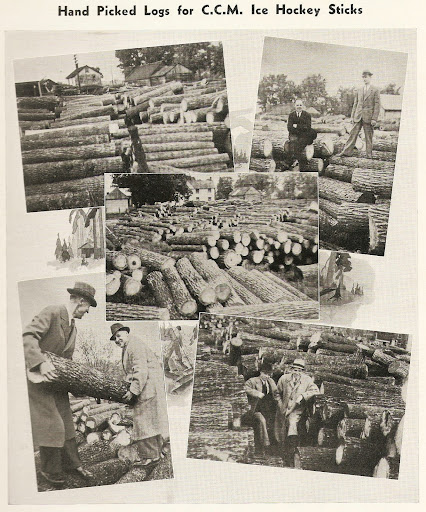

Top left: Five acres of ground piled with choice hand-picked logs to be sawed under the personal supervision of Jos. Choquette.

Top right: Standing is Mr. Ernie Everden, inventor of the C.C.M. laminated model. Sitting is W. Prince also of the factory staff. Both on a tour of inspection.

Bottom left: Mr. J. Howes C.C.M. Ontario sales manager and Mr. C. Lawrence convincing themselves that 12 lbs. of green lumber is used in the making of every C.C.M. hockey stick.

Centre: Note there are no logs of large diameter in this lot. Only second growth small trees are selected. Handle stock for the top three grades of C.C.M. Laminated Ice Hockey Sticks is taken from logs 6” to 9” diameter.

Bottom right: Mr. J.A. Russell and Mr. N.P. Tonkin seen standing between two rows of logs piled shoulder high. Note again uniform size of logs selected for the manufacture of C.C.M. Ice Hockey Sticks.

(From: 1935 CCM Sporting Goods Catalogue)

The first CCM laminated hockey stick was developed by company employee Ernie Everden and left the St. Jean factory in 1935. While early sticks had been made of a single piece of wood with the curve at the bottom created by using steam to cure and bend it, the laminated stick was made of various layers held together by waterproof glue. Everden sought and was granted a patent for a three-piece stick where the shaft and blade are separate, held together by a wooden wedge and glue. Not only was the laminate stick easier to make, there was less waste.

“We can use a lot of lumber in making these that would otherwise have to be scrapped. You see, it’s much easier by this process to make sure that both the blade and the handle are straight-grained and that a light stick will stand up in play,” explained Ed Choquette. (2)

The great Rocket Richard picks a stick from a pile of CCM lumber.

As time went on, players in the NHL began to ask for lighter sticks. While the standard weight for a stick had been 26 ounces, players looked for sticks that were as light as 17 or 18 ounces. It was a request that didn't sit well with team owners, who were now being forced to pay for an increasing number of broken sticks. Among them was Conn Smythe, the frugal owner of the Maple Leafs, who demanded his players use 25 ounce sticks no matter what their preference.

As time went on, players in the NHL began to ask for lighter sticks. While the standard weight for a stick had been 26 ounces, players looked for sticks that were as light as 17 or 18 ounces. It was a request that didn't sit well with team owners, who were now being forced to pay for an increasing number of broken sticks. Among them was Conn Smythe, the frugal owner of the Maple Leafs, who demanded his players use 25 ounce sticks no matter what their preference.

While hockey sticks were generally made to a club’s guidelines, there were a few players who could ask that their sticks be made to their own specifications. It was a practice that never found favour with CCM for it usually left the company holding a number of unwanted sticks. A player, having had the company make twelve different styles of sticks, then picked one leaving CCM holding eleven. Often the left-over sticks found their way, as “autographed models,” to be sold in Doug Laurie’s sports shop at Maple Leaf Gardens.

By 1940 the Jos. Choquette Wood Specialties Co. Ltd. was a wholly-owned CCM subsidiary known as Cho-Wood Products Ltd. By this time the company was producing 240,000 hockey sticks annually, including 125 different custom-made models for NHL players. In 1946 the company suffered the loss of Joe Choquette who died in a Montreal automobile accident. An avid amateur baseball player, in his early days Choquette had played on a ball team with Howie Morenz and Odie Cleghorn. At the height of the Canadien-Maroon rivalry, when players didn't mingle much, it wasn't uncommon to see the likes of Nels Stewart, Hooley Smith and Howie Morenz together at the same time looking for a hockey stick. It was said that when the players visited Joe Choquette, “they met on common ground.”

For many years the CCM sporting goods line was overseen by George Parsons (1914 – 1998), a former member of the Maple Leafs, who had played in two Memorial Cup tourneys before turning pro in 1935. Parson’s playing career was cut short in a game against the Chicago Blackhawks on Mar. 3, 1939, when the blade of a stick accidentally clipped his left eye cutting the retina and causing him to lose sight in that eye. Denied permission to continue playing, Parsons became a fulltime employee of CCM and eventually its Vice-President in Charge of Product Development.

It was Parsons who oversaw the development of the CCM AcuFlex hockey stick, designed to match the strength of the player with the strength of the stick. Stronger players, according to Parsons, needed a stiffer stick. With each of the AcuFlex sticks marked with bright colour bands, dealers were given a device known as a “Dynamometer”. Developed in conjunction with Dalhousie University in Halifax, the "Dynamometer" was used to measure the strength of the athlete’s grip. Once the appropriate colour was determined based on where the needle of the dynamometer pointed when gripped by the player, the dealer was then able to select the appropriate stick with the matching colour band.

One of the most colourful sticks produced by CCM was for American daredevil Evel Knievel. An avid hockey player, who once played with the Charlotte Clippers of the Eastern Hockey League, Knievel was hired by Toronto Toros' owner John Bassett to take four penalty shots on team goaltender Les Binkley between periods of a WHA game on April 11, 1975. To accomplish the task Knievel was given a CCM stick decked out in his signature red, white and blue colours. With Frank Gifford on hand to cover the event for ABC’s Wide World of Sports, Knievel used the stick to score twice, earning himself $20,000. Meanwhile Binkley used the $2,000 given him for his two saves to take his teammates out for dinner and drinks after the game.

Unfortunately, time and neglect would eventually catch up to the CCM sporting goods factory in St. Jean, Quebec, just as they would to the company's bicycle plant in Weston, Ontario. In November 1982 when Cooper Canada Ltd. was considering making an offer for the St. Jean plant, they a sent a couple of company representatives out to take a look at the operation. What they saw didn't impress them.

TWhen Henry Nolting and Jerry Harder of Cooper Canada Ltd., visited the St. Jean plant, they found only a hundred or so workers still there, most of whom were said to be apathetic and listless. The research and development department (two people) was said to be experiencing problems with their Propacs (CCM’s version of the Cooperall) and working with the Quebec Nordiques to improve the product.

The factory itself was in no better shape. The roof in the stick-making section was leaking; the offices were said to be in a mess and the warehouse was full of old stock. The boot-making operation had fared a little better, according to Harder, and could be transferred to Cooper Canada Ltd.’s Toronto location. In the end, Nolting and Harder determined the assets of the operation were certainly worth no more than “book value” and even that was a stretch. (3) It was a sad end to what had once been a glorious enterprise.

1. "Modern Plant Turns Out 240,000 Hockey Sticks For Twenty-Four Countries," VIM, Vol. 22, No. 2, 1935

2. ibid.

3. Donald H. Thain, "Cooper Canada Ltd.," London: Ivey Publishing, 1983

TttyyyyyyyyTtttthhh

Top left: Five acres of ground piled with choice hand-picked logs – 110M feet at this one mill for sawing under the personal supervision of Jos. Choquette.

Top right: Standing is seen Mr. Ernie Everden, inventor of the CCM laminated model. Sitting is W. Prince also of the factory staff. Both on a tour of inspection.

Bottom left: Mr. J. Howes CCM Ontario sales manager and Mr. C. Lawrence just convincing themselves that 12 lbs. of green lumber is used in the making of every CCM hockey stick.

Centre: Note there are no logs of large diameter in this lot. Only second growth small trees are selected. Handle stock for the top three grades of CCM Laminated Ice Hockey Sticks is taken from logs 6” to 9” diameter.

Bottom right: Mr. J.A. Russell and Mr. N.P. Tonkin seen standing between two rows of logs pilrd shoulder high. Note again uniform size of logs selected for the manufacture of CCM Ice Hockey Sticks.

the

wwww

aaaaaaaaaa